The inspector must record electrical deficiencies for electrical equipment that services more than one specific area of the building (e.g. main electrical panel) within Building Systems. Electrical deficiencies for electrical equipment that service a specific area of the building (e.g. community room, hallway, unit) must be recorded in their respective locations.

1. The inspector will not record a deficiency for missing covers or exposed bare wiring for low voltage (telephone lines, security Systems, etc.) or cable television wiring.

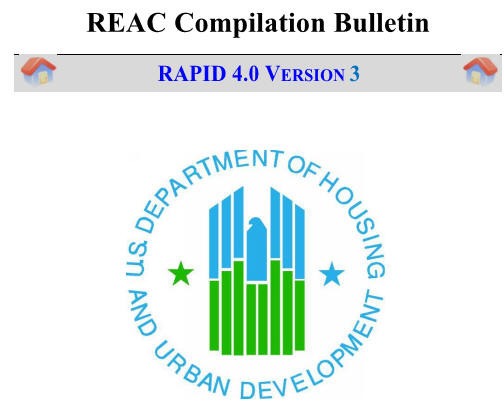

2. For the purposes of inspecting the property, all electrical components used to supply or control the supply of electricity to the building after the meter base are considered to belong to the property.

Any observed Health and Safety defects are to be recorded, even if the utility box is non-property owned. Record them under [Health and Safety], [floor level (if applicable)], [Hazards], [Any Other -This does pose a risk of bodily injury] for that building or under [Site], [Health and Safety], [building or nearest building], [Hazards], [Any Other - This does pose a risk of bodily injury], as appropriate. If the Health and Safety defect is Life Threatening, it will not automatically appear on the EH&S report and will need to be manually tracked and recorded on the Notification of Exigent and Fire Safety Hazards Observed form at the end of that day’s inspection.

4. Any electrical panel/box that is designed to have an interior cover but the cover is missing, exposing bare wires/connections at the time of inspection, will be recorded as [Missing Covers, exposing electrical connections] in the appropriate Inspectable area.

5. Electrical panels (breaker/fuse boxes) that are secured at the time of inspection (except for disconnects and timer boxes) must be made accessible to the inspector for inspection. Any electrical panel (breaker/fuse box) that is not made accessible will be recorded as [Blocked access to electrical panel] in the appropriate Inspectable area.

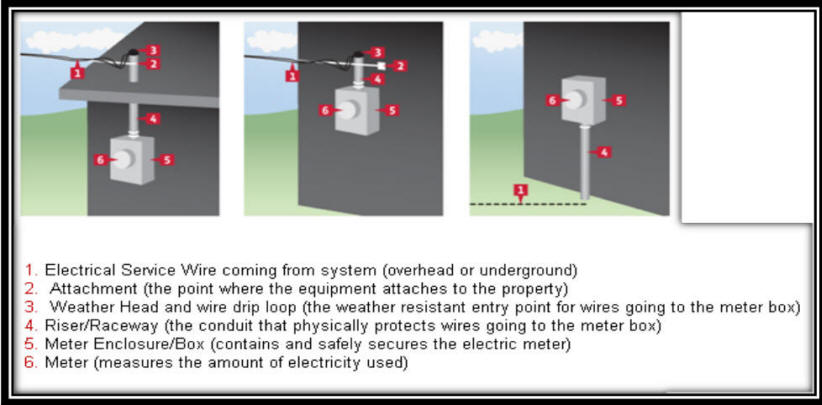

6. Electrical Panels: The introduction of any foreign materials within the panel to cover or fill a crack or opening is prohibited and (e.g. caulking, spray foam, screws, etc.), is not an acceptable repair (NIS). It shall be recorded in the appropriate inspectable area as an “H&S – Electrical Hazard” under “Opening in the electrical panel are not properly covered”. The only acceptable materials allowed in these type devices are those that are specifically designed, tested, and approved for this application.

Below are examples of unacceptable repairs:

b. If an exterior disconnect or timer box that is not associated with any other specific inspectable area has no cover resulting in exposed bare wires or connections, the inspector is to record this as a deficiency at [Building Exterior], [Health and Safety], [Electrical Hazards], [Exposed bare wires], regardless of the design of the box. If the disconnect is associated with a specific sample unit, common area or system, the deficiency would be recorded in that area.

c. An opening or gap when measured and found to be greater than a 1/4 inch between the breakers/fuses and the internal cover of an electrical panel is an electrical hazard. This deficiency is to be recorded under the applicable inspectable area as [Site, Building Exterior, Building Systems, Common Areas or Unit], [Health and Safety], [appropriate building, floor level or room location (if applicable)], [Electrical Hazards], [Openings in electrical panels], [The openings in the electrical panels are not properly covered].

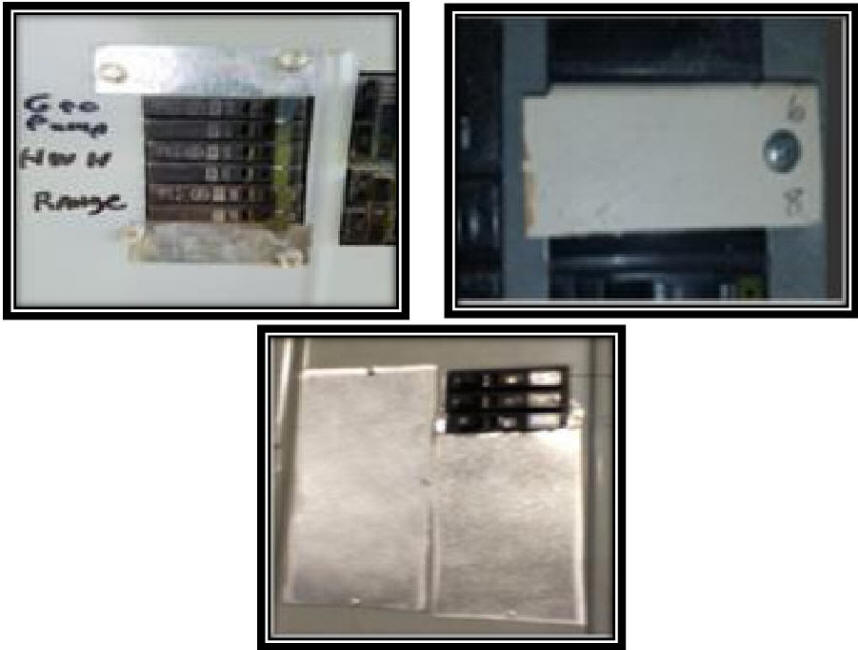

d. All surface mounted electrical devices must be inspected for any missing knockout(s). If missing, a deficiency will be recorded in [H&S], [Electrical Hazard], [Opening in electrical]

f. Inspection of Zip Ties: If the inspector sees a reason why they should be tested (e.g. sun baked, color is worn and faded, etc.) and when tested it breaks off in their hands and exposes bare electrical wiring or connections to be exposed, it is a defect. Otherwise, if the zip tie breaks when tested, but no bare wiring or connections are exposed, it is not a defect. This does not imply that every zip tie on every property must be tested, apply for this situation on a case-by-case basis.

g. Ground Fault Interrupter (GFI) - Inoperable is an automatic non-life threatening Health and Safety deficiency when recorded. Disregard the comment in the definition that says, “If this condition is a health and safety concern, you must record it as ‘Health and Safety: Electrical Hazards.”

9. Tripped Breaker: The POA can reset a tripped breaker if the breaker does not affect a life safety item such as call-for-aid or a smoke detector and there will be no deficiency observed. Note: The inspector should never turn on any breaker that is found to be in the “off” position, since he/she is not sure what appliance or dangerous condition that it might create (e.g. turns on stove). The POA should be given the option to turn on any breakers that are off. The exception to this is the testing of the GFCI and AFCI protected breakers.